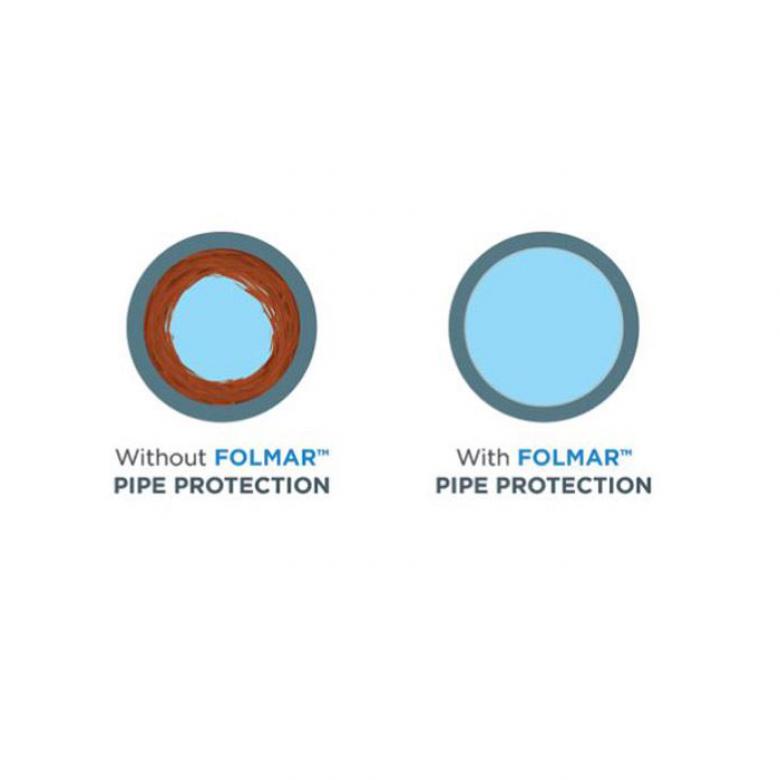

The conditions inside distribution piping greatly affect drinking water quality. Chief among the offending factors is corrosion, which in turn discolors the water and accelerates biofilm formation. The water often travels far from source to tap. Clean water is often produced through treatment, only to be contaminated once more during transport.

The distribution system is vulnerable and considerable corrosion is caused by aggressive source water, chlorine and chloramines. FOLMAR™ eliminates corrosion throughout the system, both improving water quality and lengthening infrastructure lifespan.

FOLMAR forms a closed, tight, waterproof layer between the water and the surface. The barrier stops corrosion in 3 ways. First, it acts as an electrical insulator when it chemically bonds to and neutralizes both the anodes and the cathodes. Second, it separates the vulnerable surface from aggressive water and contaminants, such as organic acids, chlorine and chloramines. Third, it creates a physical barrier that protects the metal surface from biofilm that causes biocorrosion. Further thinning of the pipe wall is thereby prevented.

FOLMAR is an efficient corrosion inhibitor which guarantees outstanding results in preventing new drinking water systems from corrosion. It also effectively addresses existing internal corrosion. The FOLMAR product is a result of the highest German Engineering Standards. This technology is successfully used in German drinking water utilities and distribution systems, with a track record dating back to 1984.

FOLMAR reacts chemically with the surface of a pipe forming a thin, mono molecular film. This barrier-film prevents corrosion reactions by preventing direct contact between the pipe surface and the water. In the case of existing corrosion, FOLMAR reacts with the corroded surfaces and stops additional degradation. As the hydro-metallic oxide layer is covered, new deposit protection is also established. Over time, FOLMAR will be absorbed onto surfaces forming a barrier film throughout the entire system – from injection point to tap. This corrosion inhibition technology considerably decreases the corrosion rate of a material exposed to a water flow, enhancing infrastructure lifespan and protection the treated water from re-contamination. FOLMAR is an effective solution for a safe water supply.

Benefits

Prevent corrosion in new water distribution systems

Control existing corrosion in water distribution systems

Avoid red water release in drinking water distribution systems

Avoid leaching of metals in treated water

Minimize the water main breaks produced by internal corrosion

Extend infrastructure lifetime

Reduce ongoing maintenance costs

Postpone capital investments

Reduce chlorine demand and disinfection by-products (DBPs)

Safeguard high water quality standard

Avoid changes of drinking water taste and odor

Protect customer’s investments in hot water heaters

Obtain more satisfied customers and improve public relations

Folmar Pipe Protection is a silicate-based corrosion and scale inhibitor for drinking water systems. It has extensive use history in Europe and other places dating back to 1984.

Folmar Pipe Protection is non-toxic, biologically inert, mineral-based, and replaces phosphates. It can be added to the water anywhere in the system with full downstream effect.

Folmar Pipe Protection is effective on all metal surfaces, including residential plumbing and appliances, and additionally protects concrete surfaces of liners, clearwells, and other reservoirs.

Folmar Pipe Protection also mitigates problems associated with the cessation of phosphate dosing by stabilizing and improving the mechanical protection layer. It also chelates iron and manganese introduced by the source water.

Folmar Pipe Protection exhibits inhibition of both anodic and cathodic reaction sites.

-

A colorless, odorless and thin liquid that is added to the water system at the plant

A colorless, odorless and thin liquid that is added to the water system at the plant -

Folmar™ Pipe Protection is dosed in-line using a peristaltic or similar dosing pump.

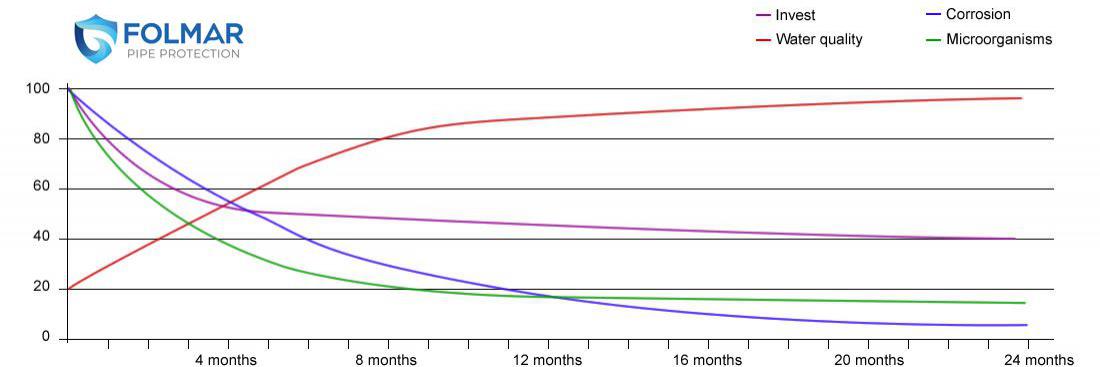

Why it makes sense, to use FOLMAR:

■ Avoidance of corrosion and red water

■ Minimization of pipe bursting

■ Extension of life span of the pipes

■ Reduction of expenditure necessary for the proper

maintenance of the infrastructure

■ prolonging replacement of the pipeline

■ Optimization of the expenditure for the pipeline maintenance

■ Decrease of the micro-biological pollution (biofilms)

■ Reduction of needed chlorine or similar products

■ Safeguarding of a high quality standard

■Termination of the lime deposits (incrustations) in warm water

devices at the final consumer

■ Satisfied customers

■ Better image for the water distribution company